windsoft

Member

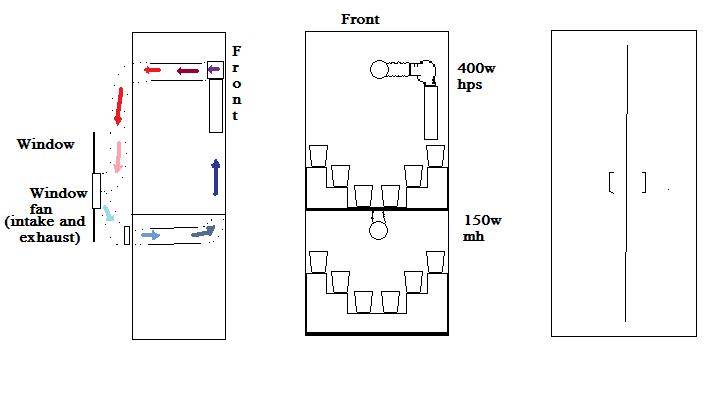

As much as I hate drawn pics, I have yet to buy the cab and get working.

I have a canfilter 9000 - two 400w hps's - no EXHAUST YET

My main questions are regarding airflow and what fan to buy. I think I can only run at approximately 100 cfm with the carbon filter I have purchased already.

I am planning on pumping in air with a PC fan and then exhaust out with something 265 or under obviously. Any comments?

I have a canfilter 9000 - two 400w hps's - no EXHAUST YET

My main questions are regarding airflow and what fan to buy. I think I can only run at approximately 100 cfm with the carbon filter I have purchased already.

I am planning on pumping in air with a PC fan and then exhaust out with something 265 or under obviously. Any comments?