You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ICMAGS Minifridge Clubhouse

- Thread starter disfunktional

- Start date

idontsmoke

Member

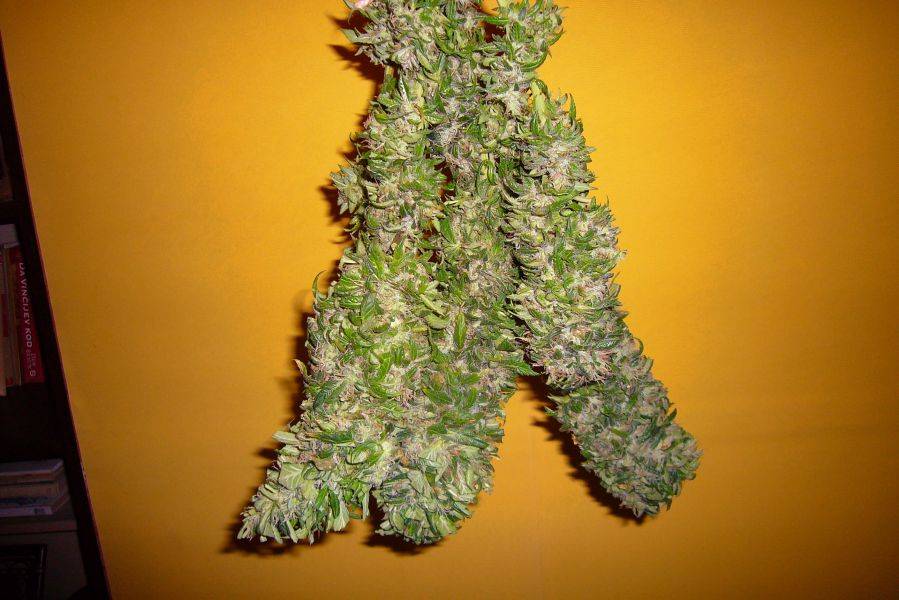

Fridge round one - harvested

Here's couple of pics...

Plant no2 harvest. Kingston USB flash drive for size reference

Plant no1 harvest. Cellphone for reference.

Plant no1 trimmed.

Weeeeeeeeeeeee i got munchies after six years

Here's couple of pics...

Plant no2 harvest. Kingston USB flash drive for size reference

Plant no1 harvest. Cellphone for reference.

Plant no1 trimmed.

Weeeeeeeeeeeee i got munchies after six years

Nice, the bottom pic looks like Roger Rabbit.

disfunktional

Member

wow awsome harvest ids. lol DB it does

hey guys, just finished gutting out all the insulation and painting the fridge....things are starting to come together. I gotta do the ventilation holes next, but I don't have access to a holesaw. Is there any other way to do it and have a nice clean circular cut? Wanna get those tubes in nice and tight. I plan on doing 4" holes, 2 in the bottom right under the hump and 1 right at the top corner.

thanks for the info, I appreciate it alot!

thanks for the info, I appreciate it alot!

disfunktional

Member

hey guys, just finished gutting out all the insulation and painting the fridge....things are starting to come together. I gotta do the ventilation holes next, but I don't have access to a holesaw. Is there any other way to do it and have a nice clean circular cut? Wanna get those tubes in nice and tight. I plan on doing 4" holes, 2 in the bottom right under the hump and 1 right at the top corner.

thanks for the info, I appreciate it alot!

Thats great news!! do you have any pics yet?

What kind of tools do you have access to? I can think of a few ways that you can make a hole but if you dont have access to a hole saw then you might not have access to the other kind of tools. The tool that will give you the cleanest hole, even cleaner than a hole saw, would be whats called a knock out. Electricians use them for electrical fittings on panels and such. Its basically a small hydraulic tool that has various sized attachments for the size hole you want. You can find small basic knock out kits at Lowes or Home Depot. Now another way you could go is useing a pnuematic cut off tool, the kind where you hold the tool and he cut off wheel is at 90 degrees from the tool. That tool will work but the hole will not be as exact as the hole saw or knock out and may require some further work with a file to clean it up. Another way you could go, and I dont recommend it, is to draw the circle you want cut out anduse a small drill bit say 3/32" or so and drill the holes along the line as close as you can. That way will definitely require some fileing and it will be very time consuming. All the tools mentioned in this post can be found at both Home Depot or Lowes and are all relatively affordable. The knock out set may need to be bought at a local electrical supply store for the size your needing.

All in all if it were me I would go with the knock out for its ease of use, the quickness of the tool, and the clean finished product. Only down side is it will the more expensive route to go. I hope this helped and i hope to see some progress pics of the fridge, I really dig under construction pics.

The metal is pretty thin, I'm not sure if you can cut a single, clean 4" circle with curved snips but you can always piece it out.

Mark the hole. Drill a hole with a twist-bit (just inside the mark) large enough to get your snip tips started. It usually works better to stay on either side of the mark than to split it. Only cut as far as the snips can make the mark. When the tips can no longer make the mark, drill a hole with the twist bit at that point, then start snipping again.

The twist bit hole is just a way to get your snips to cut a more tight circle than they might on their own.

Mark the hole. Drill a hole with a twist-bit (just inside the mark) large enough to get your snip tips started. It usually works better to stay on either side of the mark than to split it. Only cut as far as the snips can make the mark. When the tips can no longer make the mark, drill a hole with the twist bit at that point, then start snipping again.

The twist bit hole is just a way to get your snips to cut a more tight circle than they might on their own.

touchofgrey

Active member

the knockout punch dysfunctional mentioned is this http://www.google.com/products/cata...ct=result&resnum=3&ved=0CCIQ8wIwAg#ps-sellers

It's used by electricians to add knockout holes in electrical panels. It's a great tool but your best bet is to try to find a contractor rental store.

DB's on the right track I think. Your problem likely is going to clearance. Normally you're putting the vents in corners where it's hard to work a snip all the way around a circle. They make snips for LH and RH direction of cut and between the 2 you can usually get all the way around.

You could also get as much as you can with snips and finish it out with a grinding drum on a drill.

Good luck.

It's used by electricians to add knockout holes in electrical panels. It's a great tool but your best bet is to try to find a contractor rental store.

DB's on the right track I think. Your problem likely is going to clearance. Normally you're putting the vents in corners where it's hard to work a snip all the way around a circle. They make snips for LH and RH direction of cut and between the 2 you can usually get all the way around.

You could also get as much as you can with snips and finish it out with a grinding drum on a drill.

Good luck.

disfunktional, I didn't see your post and didn't know about the knock out kits. That's beats the hell out of holding your mouth right with snips.

touchofgrey remembered something I forgot.....snips suck in corners. Great input, you may have saved an unnecessary purchase of snips. The grinder drum is another great idea, a steady hand should be able to make quick work of a gnarly hole and they don't cost much, especially if one already has the drill.

touchofgrey remembered something I forgot.....snips suck in corners. Great input, you may have saved an unnecessary purchase of snips. The grinder drum is another great idea, a steady hand should be able to make quick work of a gnarly hole and they don't cost much, especially if one already has the drill.

thanks for the responses so far guys, I'll go to the local Lowes/Home Depot to check things out. I'm on a budget so cheaper is a good route, but I definitely want some quality cuts.The knockout kit sounds like the best tool to use. As for the pictures, the fridge is currently at a friends house, had to do the painting there. But I'll take some pictures the next time I go over there!

Adjustable rotary tools work better and are less dangerous on thicker materials such as cutting a knob hole through a door. Once the tool cuts through, it's hard to hold a hand drill steady enough to not booger the hole in thin materials. I'm not even sure if a carbide bit would work on sheet steel. A carbon steel bit is only good for non-metal and (possibly) non-ferrous metal like aluminum or brass.

Green Smoke

Member

I was thinking of going with an rotary tool, like a dremel with the saw but it probably wouldn't be a clean cut and as you guys said it might not cut through the sheeting. I'm gonna call the local hardware stores for a knockout kit, they definitely sound like the best way to go. I'm hoping that their somewhat cheap and have a 4" hole. But thanks for all the information so far guys, I'll post some pictures asap. Got the exhaust in the mail couple days ago. I'm gonna try to fit 4 2 gallon air pots, running Russian Rocket Fuel autoflower!

disfunktional

Member

ouch I hadnt realized how much those cost. Good call, touchofgray, on the contractor rentall supply, it will definitely be a fraction of the price.

DB I hadnt thought of the snips good idea.

DB I hadnt thought of the snips good idea.

kid_sublime

New member

hey guys, i'm new here but i am thoroughly enjoying this minifridge thread! i currently have a 1.5x1.5x3 i think? with 2 105 watt cfl's of the 5000k and 2700k spectrum's.

anyway, i also work with sheetmetal everyday and i would think i simple dremel tool with one of the small cutoff dics would work perfect for making a large hole. just mark up the diameter of the finished hole size and a second diameter inside staying within 1/32nd. grind out the smaller diameter and then finish with the sanding tumbler attachment. done!

i will also get to posting pics of my cab. keep on growing!!!

anyway, i also work with sheetmetal everyday and i would think i simple dremel tool with one of the small cutoff dics would work perfect for making a large hole. just mark up the diameter of the finished hole size and a second diameter inside staying within 1/32nd. grind out the smaller diameter and then finish with the sanding tumbler attachment. done!

i will also get to posting pics of my cab. keep on growing!!!

disfunktional

Member

Nice set up MagicChef. I bought that same digital timer, how do you like it so far?

touchofgrey

Active member

I love the idea of using a fridge and I'm pretty sure I could pick one up a dead one for free but I've got a question for the group. What do you do with the freon when you gut it out. Anyone know a good way to get a proper decomissioning?

I was thinking I could go to a place that does that and say I wanted to convert it to a meat smoker since I've seen people around here do that with freezers. Any other ideas?

I was thinking I could go to a place that does that and say I wanted to convert it to a meat smoker since I've seen people around here do that with freezers. Any other ideas?