Hey stuck,

You should host your images here @ ICMag. swecan wants to install some certificates because you used https in your links.

BTW, Nice plants

thanx

forgot about that certification(spelling?), swecan uses a fake certifikation an old one, to make safer or something.

Changed it now, and the pics are now hosted @ icmag

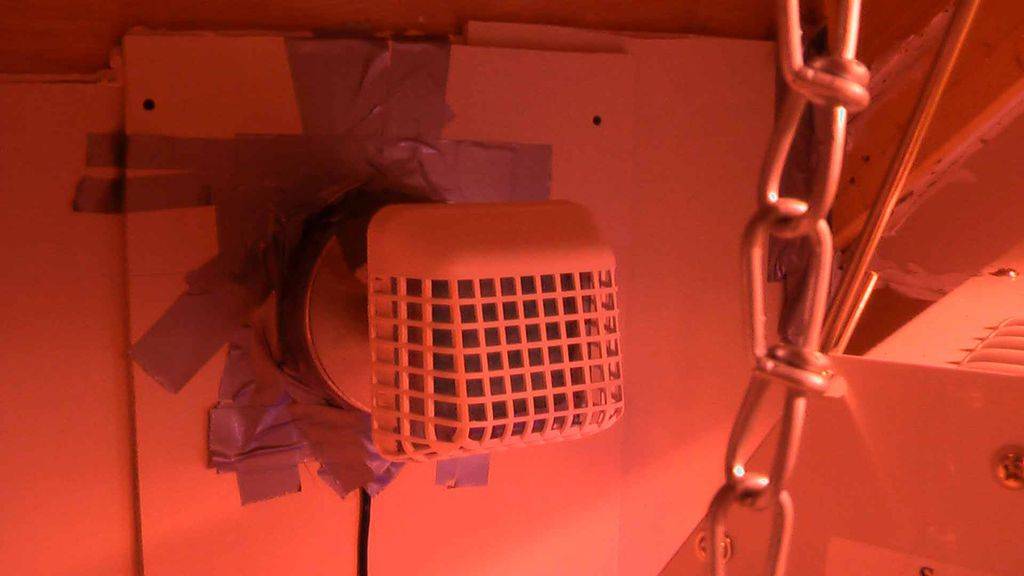

The simple answer to your question is yes, temps in your cab will increase when the light is on. However, if you have adequate ventilation, this shouldn't be an issue at all w/a 150. Why don't you tell us a bit more about how your cab is ventilated. Mainly exhaust.

The simple answer to your question is yes, temps in your cab will increase when the light is on. However, if you have adequate ventilation, this shouldn't be an issue at all w/a 150. Why don't you tell us a bit more about how your cab is ventilated. Mainly exhaust.