kp^

Member

Hello fellow growers and stoners alike!  I’m a cab/stealth grower that’s had a green thumb in years past.

I’m a cab/stealth grower that’s had a green thumb in years past.  I’ve got a good number of grows under the belt with cab style/closet growing…. I want to kick it up a notch + for medical reasons I want more sexy ladies!!! I’m testing my skills at a larger room for a medical garden. My past has been 2-4ladies and now I want to start a 16 Bio-Bucket setup. My questions are not Bio-Bucket related, or growing But overall room design, flow etc… I’m seeking advice and recommendations on my design which will improve it’s stealth, longevity, perpetual grow system etc….

I’ve got a good number of grows under the belt with cab style/closet growing…. I want to kick it up a notch + for medical reasons I want more sexy ladies!!! I’m testing my skills at a larger room for a medical garden. My past has been 2-4ladies and now I want to start a 16 Bio-Bucket setup. My questions are not Bio-Bucket related, or growing But overall room design, flow etc… I’m seeking advice and recommendations on my design which will improve it’s stealth, longevity, perpetual grow system etc….

I have approx 10feet long X 8feet wide X 8feet height.

Going with a 16 Bio-Bucket setup, ~45gallon res… lumatek 2000w…..AC, dehumidifier, Control wizard climate controller, and the 24-7 nutrient monitor. Going with 8” and 6” vortex fans, Room with have co2 in future, but not at for the first grow…. I’m still debating on the lumtatek’s… Was thinking Galexy, or something else…

For construction I’m using 2x4’s and ½” and 5/8” plywood for all the framing aspects of the room. I will be screwing everything together for various reasons…. Insulating with R15, and then covering with some thin board.. I’m still debating what I will do to cover/seal the room from within. I was thinking about sheetrock, but I don’t feel like dealing with sheetrock in general….Sheetrocking is in my blood, but I think it’s excessive for the room. I think there are better alternative thats cheaper and more flexible for the room. I

I’ve already got some good ideas for sealing/covering the exterior of the room. It’s plywood.. so I have lots of options… It might be a backdrop for a “tool” room or something…..

I live in a state that’s cool for most of the year, and I would like to intake this air if all possible. Why you ask? Cut down electricity costs of AC… If the ambient temp is cooler than the outside, pump that outside air into the grow, and the ladies will really enjoy it! Em I wrong here? Of course all intakes will pass through a filter/carbon scrubber etc… And it could be passive. Still thinking of ideas..

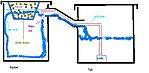

So below I share with you my work for my little medical operation I want to start very sooon. I’m trying to plan out all aspects of this now, so next month I can start buying all the supplies…. I want things done right the first time… etc. I’m putting the time and doing my research into this

I’ve got the electrician on standby to install 220 and 110 circuits for the grow…... I want lights to be on 220 while everything else… fans, meters, pumps etc are 110. This should help with loads on the circuit Im thinking…

Ok, so the room will need to be divided for a air lung..... Plus I want to keep light from leaking into the main room when opening the first door. I was thinking of the following: There are two solid interior base doors..they are pre-hung for around $60 per door.. The first door is going to make the room sealed. The second door I was thinking of the same type of door.. But looking for suggestions. Zipper would not cut it I don’t think because of the suction of the room etc.. Ideas?

Ok, images are below... I hope they answer most of your questions so I can get the best possible answers and asstiance. I'm trying to learn, and make my knowledge expand. I've still got lots of work ahead of me, but Ive got the time and dedication. I just need some help and re-assurance from other growers with more experiance than I

I've still got lots of work ahead of me, but Ive got the time and dedication. I just need some help and re-assurance from other growers with more experiance than I

Thanks all and PEACE OUT!

I’m a cab/stealth grower that’s had a green thumb in years past.

I’m a cab/stealth grower that’s had a green thumb in years past.  I’ve got a good number of grows under the belt with cab style/closet growing…. I want to kick it up a notch + for medical reasons I want more sexy ladies!!! I’m testing my skills at a larger room for a medical garden. My past has been 2-4ladies and now I want to start a 16 Bio-Bucket setup. My questions are not Bio-Bucket related, or growing But overall room design, flow etc… I’m seeking advice and recommendations on my design which will improve it’s stealth, longevity, perpetual grow system etc….

I’ve got a good number of grows under the belt with cab style/closet growing…. I want to kick it up a notch + for medical reasons I want more sexy ladies!!! I’m testing my skills at a larger room for a medical garden. My past has been 2-4ladies and now I want to start a 16 Bio-Bucket setup. My questions are not Bio-Bucket related, or growing But overall room design, flow etc… I’m seeking advice and recommendations on my design which will improve it’s stealth, longevity, perpetual grow system etc…. I have approx 10feet long X 8feet wide X 8feet height.

Going with a 16 Bio-Bucket setup, ~45gallon res… lumatek 2000w…..AC, dehumidifier, Control wizard climate controller, and the 24-7 nutrient monitor. Going with 8” and 6” vortex fans, Room with have co2 in future, but not at for the first grow…. I’m still debating on the lumtatek’s… Was thinking Galexy, or something else…

For construction I’m using 2x4’s and ½” and 5/8” plywood for all the framing aspects of the room. I will be screwing everything together for various reasons…. Insulating with R15, and then covering with some thin board.. I’m still debating what I will do to cover/seal the room from within. I was thinking about sheetrock, but I don’t feel like dealing with sheetrock in general….Sheetrocking is in my blood, but I think it’s excessive for the room. I think there are better alternative thats cheaper and more flexible for the room. I

I’ve already got some good ideas for sealing/covering the exterior of the room. It’s plywood.. so I have lots of options… It might be a backdrop for a “tool” room or something…..

I live in a state that’s cool for most of the year, and I would like to intake this air if all possible. Why you ask? Cut down electricity costs of AC… If the ambient temp is cooler than the outside, pump that outside air into the grow, and the ladies will really enjoy it! Em I wrong here? Of course all intakes will pass through a filter/carbon scrubber etc… And it could be passive. Still thinking of ideas..

So below I share with you my work for my little medical operation I want to start very sooon. I’m trying to plan out all aspects of this now, so next month I can start buying all the supplies…. I want things done right the first time… etc. I’m putting the time and doing my research into this

I’ve got the electrician on standby to install 220 and 110 circuits for the grow…... I want lights to be on 220 while everything else… fans, meters, pumps etc are 110. This should help with loads on the circuit Im thinking…

Ok, so the room will need to be divided for a air lung..... Plus I want to keep light from leaking into the main room when opening the first door. I was thinking of the following: There are two solid interior base doors..they are pre-hung for around $60 per door.. The first door is going to make the room sealed. The second door I was thinking of the same type of door.. But looking for suggestions. Zipper would not cut it I don’t think because of the suction of the room etc.. Ideas?

Ok, images are below... I hope they answer most of your questions so I can get the best possible answers and asstiance. I'm trying to learn, and make my knowledge expand.

I've still got lots of work ahead of me, but Ive got the time and dedication. I just need some help and re-assurance from other growers with more experiance than I

I've still got lots of work ahead of me, but Ive got the time and dedication. I just need some help and re-assurance from other growers with more experiance than IThanks all and PEACE OUT!

.

.