Greetings, i've been thinking lately about in-line carbon filters. Not the standard ones with minimal surface area, but taking a can style filter and making it inline. The purpose of this is two fold. The first is that it can be placed outside the grow tent. The second is that it can run after the fan(blow through, i know not best but my fan has 2 intakes which will make scrubbing the intake side difficult) but still allow me to direct the airflow out of the room the hut is in.

Basically its just taking the DIY carbon scrubber from overgrow, and a attaching 10" to 8" reducer over the main 8" to 6" reducer, and then running solid 10" duct to the top of the filter. After this would use the reducers to get back to 6"(or maybee just 8")

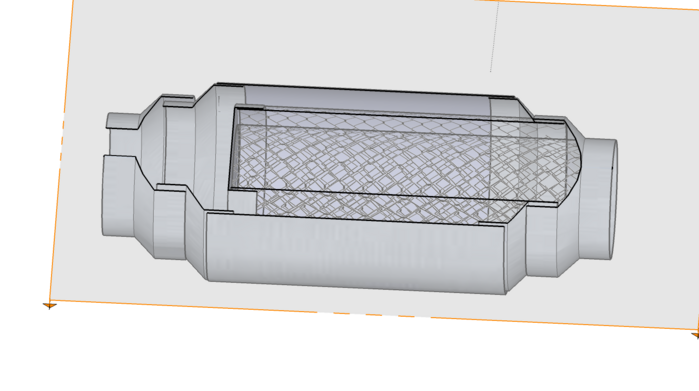

In terms of area for air flow should be good, there are 9Pi sq.in. in a 6" circle, there are also 9Pi sq. in. in a 10"-8" circle. Any reason this wouldn't work? Heres a pic i put together with google sketchup showing what i mean. The carbon would go between the two layers of chicken wire(would prob use 1/2" hardware cloth instead). Large pantyhose wrapped on the hardware cloth to hold the carbon in, all standard for a can filter basically.

Hurricane

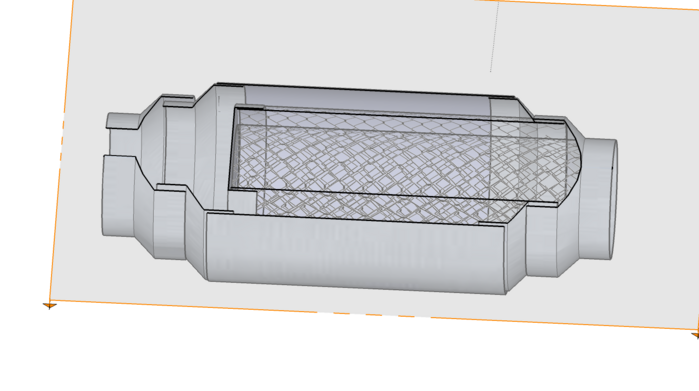

Basically its just taking the DIY carbon scrubber from overgrow, and a attaching 10" to 8" reducer over the main 8" to 6" reducer, and then running solid 10" duct to the top of the filter. After this would use the reducers to get back to 6"(or maybee just 8")

In terms of area for air flow should be good, there are 9Pi sq.in. in a 6" circle, there are also 9Pi sq. in. in a 10"-8" circle. Any reason this wouldn't work? Heres a pic i put together with google sketchup showing what i mean. The carbon would go between the two layers of chicken wire(would prob use 1/2" hardware cloth instead). Large pantyhose wrapped on the hardware cloth to hold the carbon in, all standard for a can filter basically.

Hurricane