thanks Gray Wolf.

this part I still understand. altitude is connected to boiling point.

what I don´t understand is, why does it need the pressure differential?

I thought the pressure inside the chamber is all it needs to know. (reaching a certain vacuum at which the 105F temp will make the ethanol boil)

that vacuum, no matter at sea level or Mt Everest (on the outside of the source) is irrelevant as long as INSIDE there´s a certain pressure)

how exactly will the differential influence the machine?

(sorry, if I ask he wrong question, but I don´t quite understand)

what if the wrong altitude is used? eg. 8000f at sea level. what will happen? with temp, pressure and boiling?

I only know that the liquid is used to cool down the cup. (a kind of temp-control) and if the cup runs dry, the temp will shoot up too high.

sorry, I ´m lost

How could you measure absolute pressure with no reference zero?

It is true that liquids boil at specific temperatures, based on how much atmospheric pressure is on them. Consider atmospheric pressure as a column of air one inch square, that reaches from the ground at sea level, to the outer extremes of the atmosphere and weighing the same as a one square inch X 29.92" column of Mercury, or about 14.7 pounds on that square inch.

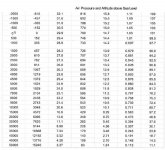

Now consider how much the remaining column weighs if you are sitting on top of a mountain, using the attached chart.

Bourdon gauges are typically used to measure pressure. Here is a link to how they work:

https://www.youtube.com/watch?v=nE_n1lCuz30

As you can see they are simply measuring the difference in pressure on the inside and outside of the coiled tube.

There are absolute measurement in$trument$, that use an internal reference, but even those have to be calibrated regularly to retain accuracy. Consider that the internal reference has to be close to absolute zero, or at 14.7psi.

To complicate it of course, atmospheric pressure at sea level also is at a reference temperature, because it varies as a function of temperature, with hot air being less dense and weighing less than cold.

Soooooo, what Extract Craft did, was reference their machines to sea level and if you are above about 1000ft as I recall, you need to re-reference it, because your machine will be looking to achieve a pressure differential that it won't be able to reach, cause it isn't there.