Quazi

Member

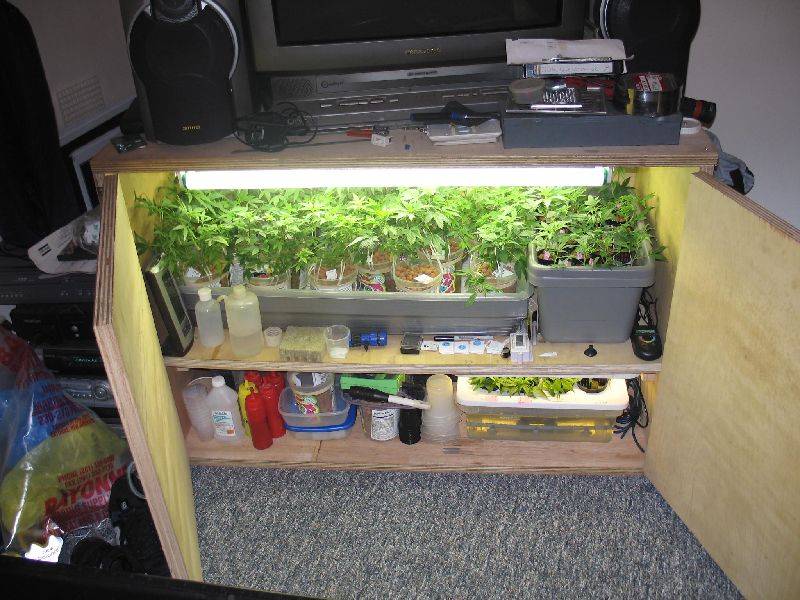

Going to be beginning construction on my 150w HPS cabinet and was curious about the ventilation.

I found some great 6" inductor fans at Lowes. You can't find them on the website so I went and grabbed some pictures. They are 160CFM free air, with up to 250CFM boosted, fans that only cost around $35 dollars. They also have an 8" 500CFM boosted fan for around $45 if my memory serves me correctly. But, the 6" 160CFM seemed enough.

A lot of the larger cabinets I have seen use blowers instead of fans. However, I've also seen people using computer fans for all of their ventilation. So, I wanted to get opinions on some others who have ventilation for their cabinets.

The cabinet is going to be around 2'Dx3'Wx3'H and I was going to use this fan to pull air through my cooling tube and be the main ventilation for the flowering chamber.

Please check out the pics and let me know what you think:

Here's what the fan looks like. It's pretty well put together from the feel of it:

I found some great 6" inductor fans at Lowes. You can't find them on the website so I went and grabbed some pictures. They are 160CFM free air, with up to 250CFM boosted, fans that only cost around $35 dollars. They also have an 8" 500CFM boosted fan for around $45 if my memory serves me correctly. But, the 6" 160CFM seemed enough.

A lot of the larger cabinets I have seen use blowers instead of fans. However, I've also seen people using computer fans for all of their ventilation. So, I wanted to get opinions on some others who have ventilation for their cabinets.

The cabinet is going to be around 2'Dx3'Wx3'H and I was going to use this fan to pull air through my cooling tube and be the main ventilation for the flowering chamber.

Please check out the pics and let me know what you think:

Here's what the fan looks like. It's pretty well put together from the feel of it:

Last edited: