Know what to do with all of that skuff you made with your bags or tumbler? Press it like the pros to keep it fresh!

Ot1's Homebuilt Hash Press

by Oldtimer1 - January 7, 2003

The finer points of pressing your skuff

Well folks, I have been pretty ill over this past year. Because of this, I was unable to care for and record the grow properly, though I may try and piece it together at a later time. I'm feeling much better now, so I thought you all might like to see another one of our toys in the mean time! It's a small hash press. It is easy and cheap to make, and, best of all, it produces an excellent quality pressed hash. So think of this as an extension of our first article on hash.

Why should you press it at all?

Traditionally, connoisseur hash producers dry their sieved skuff in a warm, low-humidity area for a few weeks. Then they seal it in airtight containers and store it by burying it or keeping it in cold rooms at near freezing temperatures for months, if not years, to allow it to mature. If done right, this maturation process reduces the amount of the volatile terpenes and improves the taste when smoked. These terpenes cause coughing and irritation to the lungs and are very evident with hash made with freshly sieved tricomes.

Dry skuff [tricomes] and hash can be stored for years at near freezing with little or no loss of the THC content. Hash made with undried skuff oxidises very quickly, loosing thc rapidly and often has mould growing through it after only a few months of storage. I have tried hash like this and it really gives me erupt-o-matic coughing fits and removes all the pleasure of smoking! I consider hash like this to be ruined beyond redemption. Some people store both buds and hash in a freezer as a long term method of storage. We did some subjective trials trying both methods and we found that that even a few days in a deep freezer causes a change in the type of high. It seems to take the top edge off and make the stone more couch lock. Other than that, we kept samples for 3 years with no apparent loss of potency. I have to say the samples kept in the salad crisper were everyone's first smoking choice rather than the freezer samples.

Hand pressed v. Larger blocks

I don't know why, but once skuff has been pressed into hash, it produces a much more complex high than the unpressed sample. Hand rubbed and hand pressed hash can be some of the finest smoking you can get. This is just fine if you are going to press small bits by hand and then use them, but not so good for long term storage. Because of the continual kneading needed to bring skuff together when hand pressing, a lot of the capitate tricomes heads are shattered throughout the mass releasing their oil.

This oxidises fairly rapidly even as it is being pressed with more and more air being mixed in as it is being worked, the whole mass becoming black right through from oxidised oil. Each piece of hand rubbed is usually only a few grams so it has a large surface area to weight for air to penetrate. Where as with direct pressing, the tricome heads in the centre mainly remain whole. They are shattered on the outer skin forming a barrier to the ingress of air and slowing oxidation internally.

Also, the blocks are in ounces, if not pounds, which means less surface area to weight ratio. So each method has its uses.

The press: instructions and parts list

There should be no problems getting all the parts from any good metal workshop. If you make a plan with a cutting list they will cut all the bits to size and drill the holes for you. Then it only takes a couple of minutes to put the press frame together.

Main Parts for the press in metric:

- 1 hydraulic car jack

- Top bar 1 x 80mm x 45mm u/formed girder cut 230mm long.

- Bottom bar 1 x 120mm x 55mm u/formed girder cut 230mm long. Both the above need 2 x 25mm clearance holes drilled approx 165mm apart centre to centre. Centred to the girder top both length and width ways.

- Side struts 2 x 25mm studding cut to 340mm long.

- Nuts 8 x nuts thread to suit studding Side struts are made from 25mm diameter high tensile studding

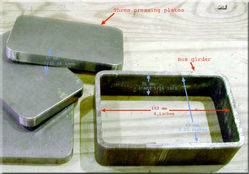

Parts for the hash former in metric:

- Former 1 x 110mm x 70mm box girder cut 30mm long.

- Pressing plates 3 x 62mm x 10mm steel bar cut 102mm long

Main Parts for the press in inches:

- Top bar 1 x 3.25 x 1.75 inch u/formed girder cut 9 inches long.

- Bottom bar 1 x 4.75 x 2.25 inch u/formed girder cut 9 inches long. Both the above need 2 x 1 inch clearance holes drilled approx 6 3/8 inch apart centre to centre. Centred to the girder top both length and width ways.

- Sides 2 x 1 inch studding cut to 340mm long.

- Nuts 8 x nuts thread to suit studding

- Side struts are made from 1 inch diameter high tensile studding

Parts for the hash former in inches:

- Former 1 x 4.25 x 2.5/8 inch box girder cut 1.5 inch long.

- Pressing plates 3 x 2.375 x 0.5 inch steel bar cut 4 inches long. The exact length of the studding will depend on the size of the bottle jack, so get your jack and build the press to suit.

Sizing and assembly

The u/girder and box girder sizes are only for a rough guide. Just use the nearest sizes your metal work shop has. Putting the press together is pretty self explanatory, but the former and pressing plates will need a little work.

- Firstly, make sure the shop cut the box girder nice and square.

- You will need to file the internal weld seam flat and remove any burrs from the box section. With a file or bench grinder, carefully round off the corners of the pressing plates to match the curved corners on the inside of the box section until the pressing plates will just slide through the box.

- Clean the inside of the box section and the plates, then lightly coat with cooking oil and rub off the excess with a tissue. This will protect against rust and work as a release agent when the hash is pressed.

Pressing method

- Put the box on a piece of tin foil or paper and slid pressing plate one into the bottom of the box.

- Cover the plate with a piece of foil cut the same size and start filling the box with skuff.

- Tamp it down with another plate (plate two).

- Keep filling until the box is full to the rim and you cant press any more in with the plate. The metric former will hold about 2 1/4 ounces/64 grams and the imperial inches 2.5 ounces/70 grams.

You are now ready to do the first press.

- Using the paper/foil, lift the hash former to the centre of the press, place the second pressing plate on top of the skuff so that it is lined up and clears the box edges.

- Put the jack on top and slowly pump until the plate is flush with the box edges.

- Release the jack and put the third plate on top of the second, taking the same care to line it up.

- Put the jack back in and pump it until it wont go any more (usually about 1/3 of the third plate goes in).

- Leave under pressure for an hour or so. When the pressure is released, the hash block expands a little so you get a slab 10 mm or 1/2 an inch thick.

Almost complete

To remove the hash from the box, lift the box from the foil/paper and the bottom plate. Plate one will drop out. Take plate three from the top. This leaves the the hash block with plate two on top of it in the box. Prop the box edges up on plates one and three under the centre of the press, making room for the hash block to come out between them. Place a piece of wood 2 x 2 x 4 inches long on top of plate two and use the jack to gently press the hash and plate two out. As soon as the foil side of the hash is touching the bottom bar, remove the jack and lift the box. The hash and the plate will drop out. Peel off the foil, then a gentle pull should separate the hash from the plate two.

You are done with hash in hand.

What are you waiting for?

The above may sound complicated, but it really only takes a few minutes to do and always works in practice. Things like adding a piece of foil on the bottom plate have come from hours of trying to get the hash out of the former box. Don't try using cling film wrapper. It can get embedded in the hash, and it's not too good to smoke. Using foil or paper under the box and plate to lift it comes from a stoned evening where I lifted the box and the bottom plate dropped out, closely followed by the skuff as I crossed the room. You just don't want to know how far 2 1/4 ounces of skuff can spread when you drop it! Ever hear of smoking the carpet? So now I try and do all the work on one table.

If your skuff has a very high sativa content in its makeup, it will be a lot less oily than if collected from indica varieties and may need a little warming to help it stick and press up nicely. If this is the case, after the first press the packed box former should be put into a very low oven. It will need about 45 mins so that it can warm right through. The oven temperature should only be as hot as you can just bare to touch. Don't over heat or you will ruin it! Once warmed right through do the final pressing as above.

How to store your final product

Finally, pressed hash keeps really well long term as long as you keep it cold and don't expose it to light or moisture. So best keep it in an airtight container close to freezing and it will be there for your pleasure whenever you need it. Remember, it doesn't matter how you extract your skuff. Using a tumbler or water extraction is just fine. The quality of the product you make will only be as good as the potency of the plants you grow. So if you grow killer Thai, you will be in for a trip. On the other hand, if you grow couch lock you will be glued to your seat. I can see you sitting there, thinking of food and not making it to the refrigerator, hehe.

Written by Oldtimer1.