I2KanGrow

Active member

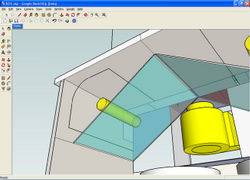

So, I've been playing with Google Sketch-Up, and I've been fascinated with the elegance of the NGB box... put the 2 together, and ya end-up doing what comes naturally - I've made modifications!!  Let me show you what I've come up with, please comment on these mods!!

Let me show you what I've come up with, please comment on these mods!!

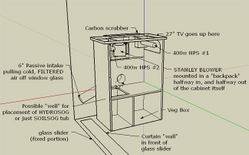

What I've done is removed all of the "plumbing", and replaced it with a "baffled manifold chamber", nestled between the grow and mommy rooms. THis 3-section chamber would exchange hot air with cold, baffle and isolate light between the rooms and the box exterior (no glowing holes - the cabinet intake needs farther mods!), and scrub the smelly air in 1 process.

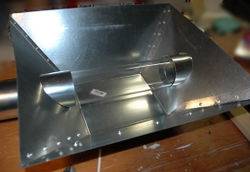

The hood is 8"x10" @ the top, 20"x22" @ the bottom, and will accomodate a Bake-A-Round cooltube. I needed to rivet 2 pieces of metal together, because I couldn't find sheetmetal large enough for my pattern (without it costing a fortune, that is - these sheets cost around $7.50 @ Lowes). After posting this, I'm gonna try to cut-it-out... wish me luck!!

This is the backside of the MicroBox.

I like the idea of having all of the venting relegated to 1 side of the box. I also want to have separate air circulation systems for the cabinet, and the light/cooltube, which should allow me the ability to vent both the MicroBox and the light with smaller, quieter computer fans. All air would be "pulled", that is to say, the cabinet fan would be located in the top-most section of the baffles, and the Cooltube fan would be located on the exhaust side of the cabnet wall.

Air would be scrubbed by pulling it thru a smaller (say 6"x6" or 6"x9") rubbermaid box that would be cut into the floor of the top-most section of the baffle. this would be sealed w/ window weatherstripping, and would be easy to lift-out, in order to to easily replace the carbon. This is very similar to Red_Greenery's scrubber, the design of which I think is pure genius!!! See Red's Thread for more details. I like the idea of creating a chimney-of-sorts, within the box, I think it will actually aid in circulating air. The light baffles would probably be made of luan, and the chamber would be painted flat black.

This is a work in it's infancy - comments?????

Let me show you what I've come up with, please comment on these mods!!

Let me show you what I've come up with, please comment on these mods!!

What I've done is removed all of the "plumbing", and replaced it with a "baffled manifold chamber", nestled between the grow and mommy rooms. THis 3-section chamber would exchange hot air with cold, baffle and isolate light between the rooms and the box exterior (no glowing holes - the cabinet intake needs farther mods!), and scrub the smelly air in 1 process.

The hood is 8"x10" @ the top, 20"x22" @ the bottom, and will accomodate a Bake-A-Round cooltube. I needed to rivet 2 pieces of metal together, because I couldn't find sheetmetal large enough for my pattern (without it costing a fortune, that is - these sheets cost around $7.50 @ Lowes). After posting this, I'm gonna try to cut-it-out... wish me luck!!

This is the backside of the MicroBox.

I like the idea of having all of the venting relegated to 1 side of the box. I also want to have separate air circulation systems for the cabinet, and the light/cooltube, which should allow me the ability to vent both the MicroBox and the light with smaller, quieter computer fans. All air would be "pulled", that is to say, the cabinet fan would be located in the top-most section of the baffles, and the Cooltube fan would be located on the exhaust side of the cabnet wall.

Air would be scrubbed by pulling it thru a smaller (say 6"x6" or 6"x9") rubbermaid box that would be cut into the floor of the top-most section of the baffle. this would be sealed w/ window weatherstripping, and would be easy to lift-out, in order to to easily replace the carbon. This is very similar to Red_Greenery's scrubber, the design of which I think is pure genius!!! See Red's Thread for more details. I like the idea of creating a chimney-of-sorts, within the box, I think it will actually aid in circulating air. The light baffles would probably be made of luan, and the chamber would be painted flat black.

This is a work in it's infancy - comments?????

Peace

Peace